Boat Stringers: What They Are, When to Know They Need Repair and How to Repair Them

Boat stringers are a critical but often overlooked part of a vessel’s structure. Hidden beneath decks and floors, they provide strength, stiffness and support to the hull and everything mounted above it. Understanding what stringers do, how they fail and how they are repaired can help boat owners catch problems early and avoid costly structural damage. Along with routine general maintenance procedures, this information ensures a pleasant experience every time you take off from a private boat dock rental or marina.

What Are Boat Stringers?

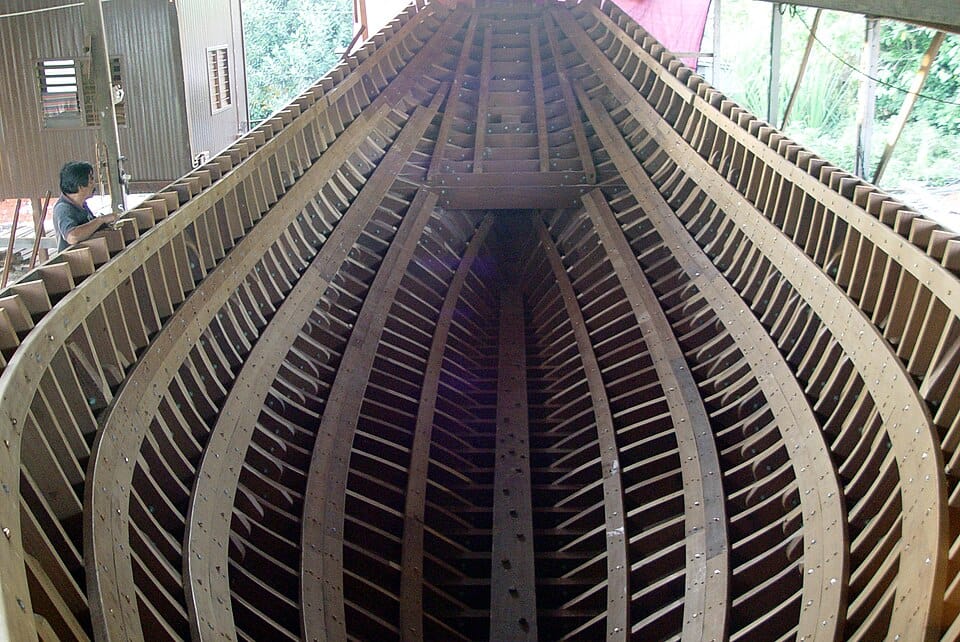

Stringers are the long structures that run fore to aft (front to back) along the inside of a boat’s hull. Think of them as the boat’s backbone and ribs combined. They reinforce the hull, help it maintain its shape and distribute loads from engines, fuel tanks, decks and passengers. Depending on the size of the boat, there can be anywhere from two to five and sometimes more stringers.

In many fiberglass boats, stringers are made from a core material (traditionally marine plywood, but sometimes foam or composite) encased in fiberglass and resin. Older boats often used wood-cored stringers, while many modern designs rely on composite cores to eliminate rot. Regardless of material, the stringer system is usually bonded directly to the hull and tied into bulkheads and transverse frames for added rigidity.

Why Stringers Fail

Stringer problems most commonly stem from moisture. In wood-cored systems, water enters through unsealed fasteners, cracks or poorly bedded hardware. Over time, trapped moisture leads to rot, weakening the core and allowing the fiberglass shell to flex.

Repeated stress also plays a role. Engine vibration, pounding in rough seas and trailering loads can cause the fiberglass skin around the stringer to crack or delaminate. Inadequate original construction or poor repairs can accelerate failure, even in composite stringer systems.

Signs That Stringers Need Repair

Because stringers are hidden, early warning signs are easy to miss. One of the most common indicators is a “soft” or spongy feeling in the deck, especially near engine mounts or high-load areas. Cracks in the gelcoat or fiberglass around the engine beds are another red flag.

Misaligned engines or drivetrains can also point to stringer issues. If motor mounts won’t stay tight or shaft alignment changes repeatedly, the underlying structure may be flexing. In severe cases, you may hear creaking sounds when the boat moves through waves or notice unusual hull flexing.

A more direct test involves tapping the fiberglass over the stringers with a small hammer. A dull thud instead of a sharp knock can indicate delamination or rot beneath the surface. Moisture meters and inspection holes can provide further confirmation. This is a quick task you can do at the marina or private boat slip for rent near me.

How Stringers Are Repaired

Stringer repair ranges from localized reinforcement to complete replacement, depending on the extent of damage. Minor issues, such as surface cracking or limited delamination, can sometimes be addressed by grinding back the damaged fiberglass and adding new layers of fiberglass cloth and resin to restore strength.

For rotted or severely compromised wood-cored stringers, full replacement is usually the only reliable solution. This is a labor-intensive process that begins with removing the deck or sole to access the stringers. The damaged stringer is then cut out, taking care not to compromise the hull.

A new stringer core (wood, foam or composite) is shaped to match the original dimensions and bonded to the hull with thickened epoxy or polyester resin. Fiberglass cloth and mat are then laminated over the core, tying it securely into the hull and adjacent structures. Proper tabbing and overlap are essential to ensure the repair is as strong as, or stronger than, the original construction.

Once cured, engine beds are reinstalled, alignment is checked and the deck is replaced. Attention to sealing fasteners and penetrations during reassembly is critical to prevent future moisture intrusion while on the water, stored at a private boat lift rental or moored in a marina.

Preventing Future Stringer Problems

Whether you keep your boat at a marina or at a private boat lift rental near me, prevention of stringer damage starts with keeping water out of the structure. All deck fittings, engine mount bolts and hardware that penetrate the hull or stringers should be properly bedded and periodically inspected. Keeping the bilge dry and fixing small leaks early can prevent major structural repairs later.

Regular inspections, especially on older boats, help catch issues before they become serious. By understanding how stringers work and what warning signs to watch for, boat owners can protect the structural integrity of their vessels and extend their useful life for many years.